Printing inks for pad and screen printing

An overview of our printing inks and pastes

Our printing inks or pastes are composed of a blend of color pigments, binders, and solvents. The color pigments provide the color to the ink, while the binder allows it to adhere to the surface. The solvent is used to dissolve and dilute the ink to enhance workability.

Due to their high viscosity, our printing inks or pastes can be applied in screen printing or pad printing, resulting in precise and uniform layers.

Screen printing and pad printing inks

Glossy printing inks are available for printing on pre-treated polyethylene, polypropylene, PVC, aluminum, etched copper, sheet metal, stainless steel, and most painted substrates. Additionally, various adhesion additives are available for printing on polyester, glass, and ceramic surfaces.

When using screen printing, it is recommended to use a mesh with 60 to 120 threads per centimeter and a polyurethane squeegee rubber (hardness: 75 Shore). The emulsions used should be solvent-resistant.

Metallic effect inks

Additionally, we provide metallic effect inks such as silver, gold, or bronze, which are produced by incorporating aluminum, brass, or copper particles. These metallic effect inks can be further overprinted with a corresponding clear varnish to enhance outdoor durability.

You can find more information and a color chart for our printing inks here:

Functional inks

Cold state

Hot state

Thermochromic inks

These are pastes that change color depending on the temperature. Thermochromic inks are based on thermochromic pigments in binders that change color when a certain temperature is exceeded. This process is reversible, meaning that the original color state is restored at a lower temperature.

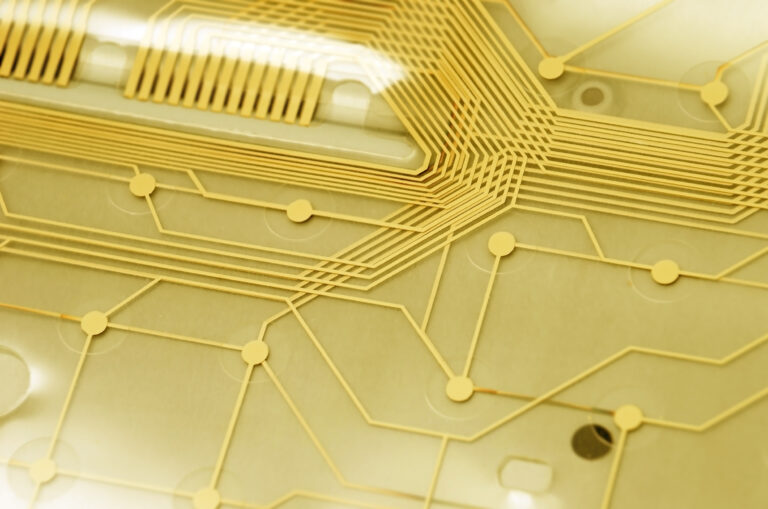

Inks for printed electronics

We provide conductive inks for printing electrical conductive traces, resistors, simple passive sensors, or heaters. The starting materials consist of conductive particles (such as silver, copper, and gold) suspended in a binder. After printing, the inks are cured by heating, reaching their maximum conductivity. The conductivity can also be improved through an additional optical sintering process.

For electrical insulation, we provide dielectric inks for applications requiring high insulation resistance, such as printed capacitors, inductors, or filters. These inks are composed of a mixture of dielectric materials (such as barium titanate, aluminum oxide, zirconium oxide, titanium oxide) and a binder that holds the ink together.

Please note that we also have other printing materials available in our product portfolio. If you have any questions or need more information, do not hesitate to contact us. We're here to help!